Products > uLPR Sensor

Overview

Analatom's micro-linear polarization resistance (uLPR) corrosion sensors provide direct real-time measurements of electrochemical activity for structural health monitoring (SHM) applications. Utilizing established linear polarization resistance (LPR) technology, sensors output an identical corrosion rate for the metallic structure on which they are placed, as they are constructed from the same temper and alloy. These ultrathin flexible sensors can be placed on bare metal surfaces and beneath coatings to allow fitting to virtually any surface.

Two-Electrode Corrosion Sensor

Using photolithography it is possible to manufacture the uLPR sensor from a variety of standard engineering construction materials varying from steels for buildings and bridges through to novel alloys for airframes. The micro sensor is made up of two micro machined electrodes that are interdigitated at 150-300um spacing. The uLPR sensor is made from shim stock of the source/sample material that is pressure and thermally bonded to Kapton tape. The shim is prepared using photolithographic techniques and Electro Chemical Etching (ECM). It is further machined on the Kapton to produce a highly ductile and mechanically robust micro sensor that is very sensitive to corrosion.

Material / processes used to produce each uLPR sensor

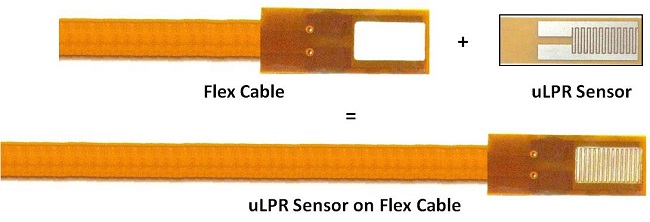

Assembly of two-electrode LPR onto a flex cable.

Available Materials

- Aluminum Alloy (AA) 2024-T3

- Aluminum Alloy (AA) 7075-T6

- Carbon Steel (CS)1010

- Copper

- Nickel 201

- Stainless Steel

- Custom (based on request).

Two-Electrode Time-of-Wetness (ToW) & Salinity Sensor

The ToW and salinity can be measured by using the resistance (or conductivity) measured between the two interdigitated LPR electrodes provided the electrodes are made from an inert metal, such as gold-plated copper.

ToW Sensor

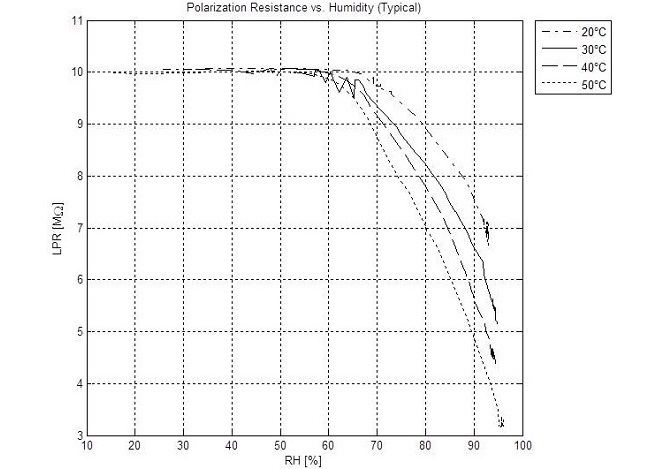

By definition, the ToW is the amount of time elapsed when the relative humidity is at least 80%. The figure provided below shows the relationship between the measured resistance between the counter and reference electrodes for different values of relative humidity for four different temperature conditions. The data was collected using a calibrated environmental temperature / humidity chamber (TestEquity 123H). The time of wetness is determined by setting a threshold value for the resistance corresponding to the point at which the relative humidity is at least 80%. Then, the time of wetness is computed as the amount of time the resistance was recorded below the threshold. According to the calibration data, the threshold can vary between 7MW to 9MW based on temperature. If the temperature variation is small, for example 20°C to 30°C, the resistance threshold can be set at 8.5MW (±4%) which corresponds to 80% humidity (±4%). If the temperature variation is larger, for example 20°C to 50°C, the resistance threshold can be set at 8MW (±15%) which corresponds to 80% humidity (±7%). For field applications this error is acceptable as in most cases the relative humidity will approach 100%, or saturation, when water is present between the electrodes of the device.

LPR vs percentage of relative humidity for different operating temperatures.

Salinity Sensor

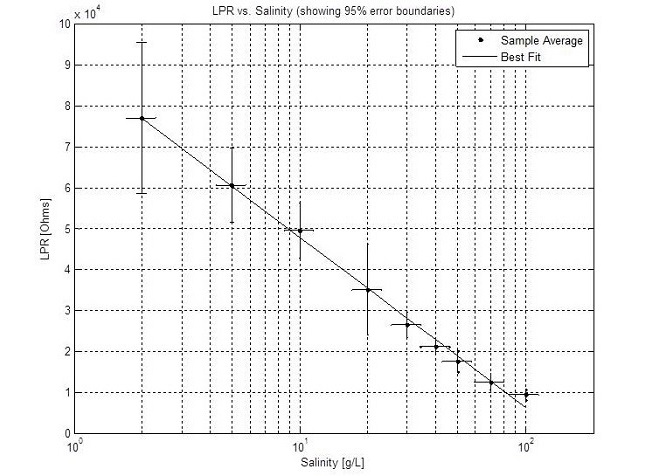

By definition, salinity is measured as the ratio of the amount of salt (in grams) dissolved in a liter (or kilogram) of water. Units can also be expressed in parts per thousand. The figure provided below shows calibration data from an experiment which eight separate sensors were placed in a beaker with a stir bar with 500mL of distilled water. Sodium chloride Fcc/usp grade 99.8% was weighed using an analytical balance and added to the beaker in incremental amounts. The average resistance measured between the interdigitated electrodes was computed along with the standard deviation and plotted in a log plot as resistance vs. salinity. An empirical relationship was derived from a linear fit of resistance vs. the log of salinity. Using this relationship, the salinity can be inferred from a measure of resistance.

LPR vs salinity for different values of salinity from 2g/L (0.2%) to 100g/L (10%).