Case Study

Borescope Inspection Automation reduced lead times by 70%

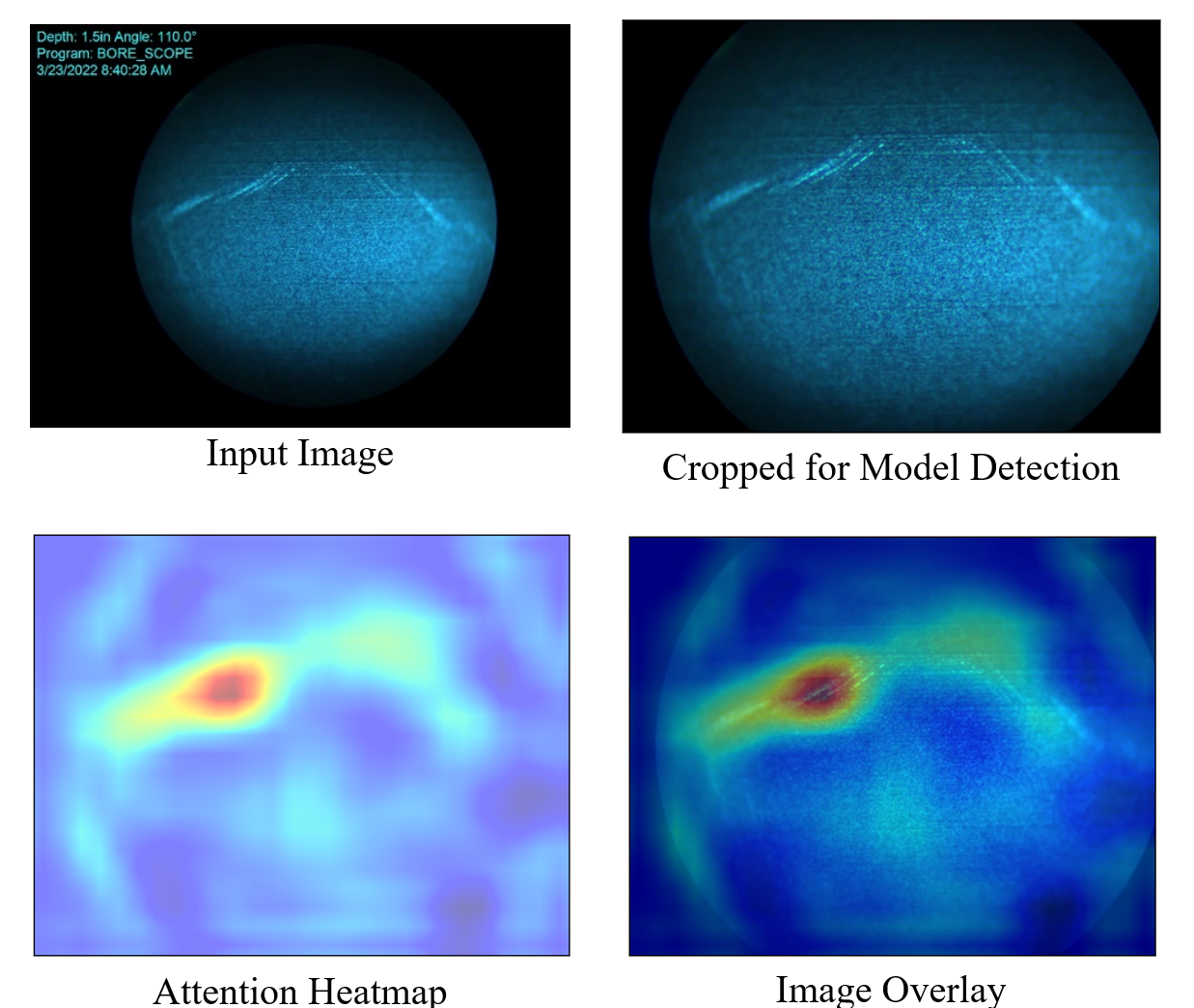

Previously, MRO technicians at Robins Air Force Base relied on a time-consuming process for borescope inspections. They inserted the borescope into the engine or component, captured dozens of images, and then painstakingly reviewed each one by hand, marking any defects on paper forms. With the introduction of AIDL software, this entire workflow was transformed. Using computer vision, AIDL automatically identifies and flags defects within the inspection images (Figure 1), allowing technicians to focus their attention on only the most critical or ambiguous cases. Their feedback on these edge cases is then fed back into the model, continuously improving its accuracy over time. The digital output of AIDL allows users to quickly export inspection results or generate a digital damage map that mirrors the manually created versions. By reducing the manual workload and improving accuracy, Robins AFB reported a remarkable 70\% reduction in inspection time, highlighting the efficiency gains and reduced labor cost achieved through this AI-powered solution.

Model identification of a defect from a borescope on a C-130 propeller blade installment.